Laser Printers Faults FAQ

Paper

Modern copiers and MFPs are one of the marvels of the digital age...it may sound silly. Not too long ago, office copy rooms used offset presses. After a day of squeezing tubes of ink onto rollers, we'd all have a greater appreciation for today's advanced machines.

Although office print solutions have evolved, they still share one main ingredient with their predecessors: paper.

That said, there are some basic paper properties that anyone who has ever loaded an empty printer paper tray should learn:

- Curl

- Weight

- Grain

- Calliper

Moisture content

Moisture content

Why are these things relevant to you? It's simple — understanding these factors is the key to producing high-quality print jobs, with the lowest instance of jamming or malfunction. Read on to get started reducing your printing headaches!

Paper Jams in the cassette

WORN OR DIRTY PAPER FEED TYRES

The Laser printer jams in or around the paper cassette, these jams are sometimes accompanied by a grey mark in the centre of the paper about a inch in from the lead edge. The mark occurs when the primary paper feed tyre slips on the paper, this is usually due to either dirty paper feed tyres or worn paper feed tyres, this will require s service to clean or replace the tyres which come as a kit. The comprises of Primary and Secondary feed tyre and a Separation Pad these should all be cleaned or changed together.

PAPER GUIDES

Another common cause of problems are the paper guides, most modern printers are made for a worldwide market, and so the paper cassettes are adjustable using the blue levers 1 and 2 opposite.

CAUTION when changing paper it is very easy move these guides, they only need to move 2-3mm for this to cause paper jams. Always ensure that the guides are pushed up tight to the paper.

PAPER SIZE INDICATOR

The dial usually located on the front of the paper cassette tells the laser printer the size of the paper in the cassette.

CAUTION The size indicated on the dial tells the machine the length of paper to be fed, if it is set to A4 the machine will expect a sheet 210mm long to be fed. If the dial is set to A4, but A3 paper is in the cassette the paper length will be 420mm long so the paper jam detect switches will be held down longer than expected and the machine will stop with a paper jam indication.

FUSER UNIT

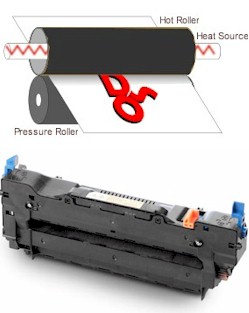

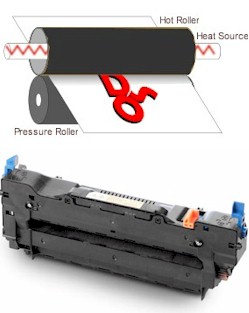

FUSER UNIT

The fuser unit in your Hewlett Packard, HP laser printer heats and crushes the toner on to the paper.

This is done with a pair of rollers (just like an old fashioned mangle) the upper roller is aluminium with a hollow core which contains a heating element. The outer surface of this roller is either Teflon coated or has a Teflon belt that runs on it. Teflon is used to stop toner (toner becomes tacky when hot) sticking to the roller.

It also has a roller pressure roller that applies the necessary fixing pressure.

There are also 4-5 picker fingers that help to separate the paper from the heat roller.

A fuser unit is a consumable part (it has a life expectancy) on average they will produce 60,000 pages.

Note - New fusers units have a gloss finish to them as they get older they become matt in appearance, you can also usually see 4-5 distinct lines where the picker fingers have worn the surface, these marks may appear as black lines if the Teflon has completely worn through to the aluminium core.

When toner starts to stick to a heat roller it will continue to build until it actually starts to make impressions in the paper.

FUSER UNIT JAMS

This occurs when the Teflon coating of the heat roller becomes damaged or wears out through use. When this occurs toners sticks to the damaged surface as a tacky lump, (these can sometimes indent the paper) this will then offset repeatedly down the length of your prints usually the marks are about 6 - 7 cm's (the circumference of the roller/belt) apart. When this type of dots appears our mobile technicians can sometimes remove the dot if its sticky glue from labels, or if it is damage to the Teflon coating then you will require a new or refurbished fuser unit.

Note - Offsetting can sometimes be caused by damp paper, the laser printer needs to get the surface of the paper above 170'c for the toner to fuse properly. If the paper has a high moisture content it may not reach this temperature so the toner is only partially fused to the paper, the excess un fused toner will remain on the fuser roller and be offset down the remainder of the print.

LINES, MAY APPEAR ALL THE MAY DOWN THE LENGTH OF A PRINT

This happens when the surface of the Teflon becomes damaged around the whole of its circumference (this also may appear as an indented line as toner builds up). This usually happens due to wear from the picker fingers. These are little Bakelite fingers that run on the surface of the heat roller to help separate the paper from the heat roller during the fixing process. When this type of line appears you will require a new or refurbished fuser unit.

PAPER CONCERTINAING

This usually happens when something blocks the exit of the fuser unit, this can be a dislodged picker finger or dislodged fuser exit switch, the paper gets stuck behind the blockage*. As the paper is continued to be fed by the fuser the paper folds up into a nice little fan. Our mobile technicians can relocate dislodged picker fingers or exit switches, if the unit proves to be broken then we can fit a replacement new or refurbished fuser unit.

*Caution - When paper gets stuck behind a picker finger, client will not be able to find the jammed paper. When they shut the printer back up it will come to ready and you can print again, this print job will just get stuck behind the first jammed sheet of paper and so on. We have had a call today from a client we found 15 sheets of paper wrapped around the fuser. The machine had continued to try and work until the main board blew, machine written off.

CREASED PRINTS, PRINTS RUBS OFF ONE SIDE

For any laser printer to produce clean crisp prints you require adequate fixing pressure, creased prints usually occur when one of the fuser units bearings collapses giving uneven fixing pressure, this will cause creasing or the print to be poorly fixed. Our mobile technicians can relocate dislodged bearings, if the bearing has failed then we can fit a replacement new or refurbished fuser unit.

Moisture content

Moisture content

FUSER UNIT

FUSER UNIT